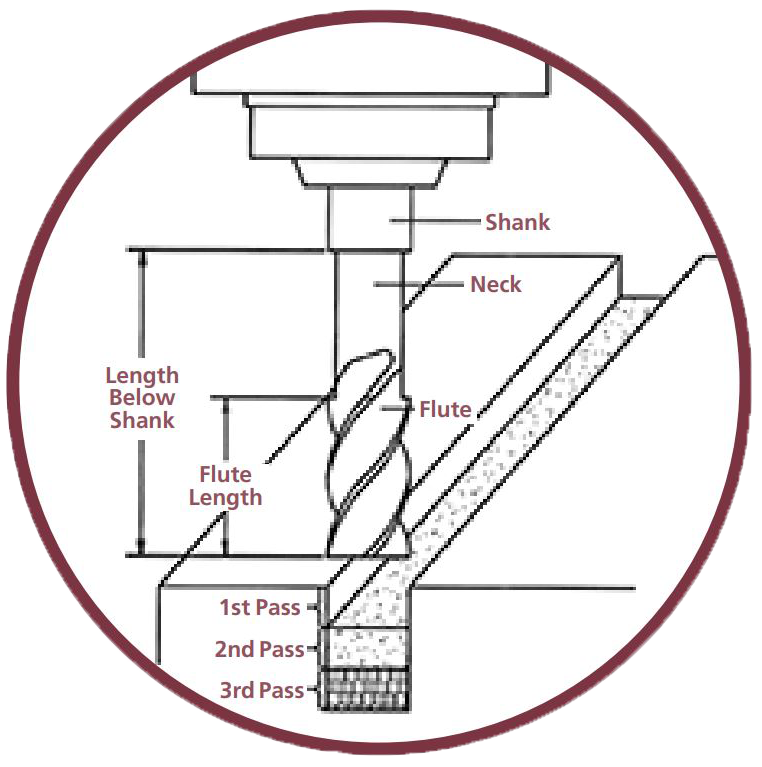

Neck Relieved Tool Application

Deep Pocket and Slot Milling with Neck Relieved Series End Mills

Necked end mills for extended reach minimize tool deflection. The rigidity of these end mills enable multiple passes at faster feed rates. The appropriate depths of cut per pass are as follows: One half (1/2) times the diameter in ferrous materials and one (1) times the diameter in non-ferrous materials. The diagram at right shows 3 passes. The number of passes will vary, depending on depth of the pocket. Call us with your specific application.

Trouble Shooting Guide

| PROBLEM | CAUSE | SOLUTION |

|---|---|---|

| Chipping | Feed to fast LooseTool Loose Workpiece Tool not rigid enou gh |

Reduce feed rate Tighten screws Tighten clamps Try shorter length end mill |

| Rapid Wear | Speed too fast Hard metal Feed rate too slow Improper cutting angle Primary relief angle too small |

Use slower speed Add coating Inrease feed rate Adjust cutting angle Use a larger relief angle |

| Breakage | Feed rate too fast Cutting amount too large Flute length too long Too much wear |

Decrease feed rate Take smaller cut per tooth Try shorter flute length Regrind sooner |

| Chattering | Feed and speed too fast Machine and holder not rigid enough Relief angle too great Workpiece too loose Cut too deep Flute length too long |

Adjust feed and speed rates Use appropriate machine or holder Use smaller relief angle Refixture part Use shallower cut Try shorter flute length |

| Short Tool Life (Dull Teeth) | Cutting friction too great Improper cutting angle |

Regrind more frequently Adjust primary clearence angle |

| Chip Packing | Cutting amount too great Not enough chip room Insufficient coolant |

Modigy feed or speed rates Use different end mill Use additional coolant or use air flow |

| Rough Surface Finish | Feed rate too fast Speed rate too slow Too much wear No end tooth concavity |

Decrease feed rate Increase feed rate Regrind soon Add more dish to bottom teeth |

| Burring | Primary relief wearing Improper cutting angle |

Regrind more frequently Adjust cutting angle |